Talk Like A Woodworker

Before you telephone a lumber company you may need to learn a little lumber talk. Hardwood lumber is sold in several grades, several thicknesses and in random widths and lengths. Lumber grading is a complicated endeavor. The grading rules were developed by the furniture industry where boards are cut into small parts and seldom used as large pieces. A desirable board will yield many of these small useful parts. Therefore, the number and size of clear cuttings available in a board is the main consideration in these grading rules. A mostly clear board, with a big knot in the middle, can still earn a high grade.

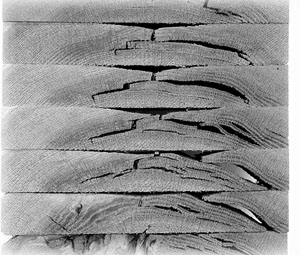

Lumber suppliers generally handle one or two grades. The highest grade available at most dealers is called Select & Better. These boards have few knots and are "wide" and long. Another, lower quality and harder to find, grade is Number 1 common. With more defects and knots, Number 1 boards tend to be narrower, and about 30 percent cheaper. Some dealers will take a picked over pile of Selects and sell it as Number 1. This pile will have a whole range of defects: twist, decay, warp, checks, splits, wane, knots, honeycomb and crook. These are not truly Number 1 common. A Number 1 board should be flat and consist of sound wood. The grading rules only allow for it to be narrower with fewer possible clear cuttings. Since Number 1 boards often come from the heart of a tree, they likely have developed deeper color and more interesting grain than the Selects. Knots are easy to band saw around, so I choose No. 1 when I can.

Lumber thicknesses are measured in the rough (before planing) and are 4/4 (four quarter), 5/4 (five quarter), 8/4 (eight quarter), etc. When smoothed with a planer they lose almost 1/4 inch of thickness; therefore, 5/4 lumber will plane to 1 1/16 inches thick. Since hardwood is cut in random widths and lengths, it is sold by volume. The standard unit of measure is the board foot. One board foot, (bd.ft.), is equal to 144 cubic inches or a piece 12 inches by 12 inches by 1 inch thick. This horse can be made from somewhat less than 10 bd.ft. Check the prices; at $3.50 per bd.ft. your wood will cost about $35.00. Also pay the lumber company to plane the wood and sand it if they can. A fee of $5.00 to $10.00 is fair for this service. Let their large machines do the brute work so you are able to concentrate on the fun parts. An industrial sized thickness sander will remove planer marks and leave you with less sanding to do. If you choose a board 5/4 inches thick by 9 inches wide by 10 feet long, with few defects, you will have more than enough wood for the horse. (About 9.5 bd. ft. - Remember to multiply by 1.25 to compute the board footage of 5/4 lumber.)

I recommend you choose a board as wide as the horse's head; 9 inches.

Another important characteristic of lumber is moisture content. Trees are saturated with water and they begin drying as soon as the roots are detached. Careful control of the rate and conditions of this drying is vital to make quality lumber. As wood loses moisture it begins to shrink and many defects in lumber result from drying too fast. A great deal of experimentation has determined the proper temperatures, air circulation and humidity needed for the production of quality lumber. The drying process is controlled by placing lumber in a dry kiln. A kiln is a large oven where wood is stacked carefully with spacers between the boards. Powerful fans and heaters warm the wood and evaporate most of the moisture. The kiln operator is usually the most experienced worker available. Wood dried too fast will be suitable for only firewood. Wood dried too slowly wastes expensive energy and kiln space. The kiln operator has a great incentive to push the lumber through the kiln as fast as possible, sometimes too fast. A small percentage of boards will degrade under the best kiln operator, so check the boards you choose carefully.

Ask the lumber company folks how dry the wood is. You want your wood to have a moisture content of about 7 to 8 per cent. A claim that the lumber is kiln dried isn't a guarantee of quality, since the wood may have been improperly kiln dried or it may have picked up moisture during storage. Nearly all lumber sold by reputable hardwood lumber companies is about 7 to 8 percent. Ask them to be sure. (Lumber purchased and used in dry climates should be about 6 percent.) Beware of that stack of lumber stored in Uncle Fred's basement or barn. This can be a great source of lumber, but haul some to a local cabinetmaker and ask them to check it with their moisture meter before you spend hours working it. Lumber stored haphazardly can have moisture levels of 12 to 20 percent; far too moist. Shrinkage occurs as this wood drys and it is not uniform. Uneven grain around knots will shrink unpredictably. The change in dimension across the grain can be ten times that along the grain. Exact moisture levels are difficult to determine without an electronic moisture meter, but high moisture levels will cause significant problems weeks or months later. Such wood will twist and crack as it dries and ruin your horse.

People offer me various piles of lumber that are claimed: to have been stored thirty years in grandpa's barn, or to have been purchased long ago for a never completed project, or to have come from resawn barn beams, etc. I have occasionally found beautiful and unusual wood in this manner. So these sources are interesting and worth checking out, but the lumber frequently is too moist, too warped and too infested with powder post beetles. Unfortunately, most of my finds have been of the latter quality. Be cautious.

They were friends, as only a craftsman can be, with timber and iron. The grain of the wood told secrets to them.

The Wheelwright's Shop

George Sturt

“I don’t say that I could afford to buy burl maple, walnut, and cherry for wood-work,” said the Harvester. “I could not, but since I have it, you can stake your life I won’t sell it and build my home of cheap, rapidly decaying wood. The best I have goes into this cabin and what remains will do to sell. I have an idea that when this is done it is going to appear first rate. Anyway, it will be solid enough to last a thousand years, and with every day of use natural wood grows more beautiful. When we get some tables, couches, and chairs made from the same timber as the casings and the floors, I think it will be fine. I want money, but I don’t want it bad enough to part with the BEST of anything I have for it. Go carefully and neatly there; it will have to be changed if you don’t.”

Gene Stratton Porter

The Harvester

There are ways of killing a cat besides choking it with butter, says a popular phrase, and it is the same with any particular thing in the workshop - if it cannot be done in one way it can in nine cases out of ten be successfully accomplished in another.

Workshop Makeshifts 1898

Hans Cassal

This fellow will but join you together as they join wainscote; then one of you shall prove a shrunk panel and, like green timber, warp, warp.

As You Like It - 1598

William Shakespeare

When uneven drying progresses, especially in air drying, an outer dry shell develops, isolating by a sort of "case hardening" the center part of the stick, which cannot dry; or at best dries exceedingly slowly, taking perhaps years. Not uncommon for the core, when it finally does dry, to then pull away from the outer shell, causing what is known as "honey comb," or "hollow horn."

The Mechanical Properties of Wood-1914 Samuel Record

It is remarkable what a value is still put upon wood,

a value more permanent and universal than that of gold.

Walden - 1854

Henry David Thoreau